| Surface Plates |

We manufacture and supply a wide range of surface plates, which are used in

various industries for tool making, inspection, spotting, gauging etc. Our

range of surface plates are specifically designed to provide an accurate

reference plane for work inspection and also for work layout. These surface

plates are strictly in compliance with international quality standards and can

also be customized as per the specifications laid down by our clients.

Our range of surface plates includes cast iron surface plates, precision cast

iron surface plates and precision granite surface plates. |

|

Granite Surface Plates

Granite surface plates are

manufactured using natural

black granite tone, quarried

from earth in its natural

form. These precision granite

surface plates are precision

lapped to high standards of

flatness to achieve accuracy

and are used as bases for

mounting sophisticated

mechanical, electronic and

optical gauging systems. Our

quality inspectors and

engineers put a strict

vigilance at all the stages of

ensure high quality plates.

Further, the final inspection is

carried out by a high

precision computerized

electronic level made by

Wyler Of Switzerland. Our

range of precision granite

surface plates are utilized in

Precision tool rooms,

Engineering industries and

Research laboratories.

|

|

Cast Iron Surface Plates

We offer a qualitative range

of precision cast iron surface

plates. These cast iron

surface plates provide an

accurate reference plane for

precision gauging, inspection

and tooling setup.

We make use of good quality

closed grain cast iron that is

as per the IS 210:1993

confirming to Grade

FG-220.The meticulous

manufacturing processes

that are carried out at our

premise makes these cast

iron plates apt for machine

shops, quality control and

standard rooms. Our

precision cast iron surface

plates are utilized in the

applications, where strict

accuracy required hence,

these plates are appropriate

for high precision work and

are ideal for blue matching.

|

| --------------------------------------------------------------------------------------------------------------------------------------------------- |

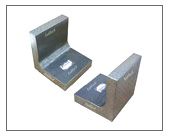

| Angle Plates |

Backed by a team of experts, we are engaged in offering a qualitative range

of angle plates, box angle plates and C.I. cubes. These angle plates are

manufactured using high grade material, which is sourced from dependable

vendors. The procured material bespeak of genuineness that ensures our

range of products are stress relieved, resistant against distortion and have

high tensile casting. These precision industrial tools are used in diverse

engineering industries and are high in demand amidst our clients worldwide.

The detailed description of angle plates manufactured under this category

includes box angle plates, cast iron cubes, slotted angle plates and plain angle

plates.

|

|

Slotted Angle Plate

We manufacture and supply a

wide range of slotted angle

plates, which are largely sed

in various industries for

clamping and holding work in

vertical position. These

slotted angle plates are also

used as a vertical reference

for inspection and tooling

purposes such as shaping,

planning, milling, grinding,

drilling etc. All 6 working

faces of our angle plates are

hand scrapped to desired

accuracy and are square/right

angle to each other.

Fabricated using high quality

closed grain cast iron of

Grade FG-220, these angle

plates comply with IS

2554:1971 standards.

|

|

Plain Angle Plate

a wide range of plain angle

plates, which are largely

used in various industries for clamping and holding work

in vertical position. These

plain angle plates are also

used as a vertical reference

for inspection and tooling

purposes such as shaping,

planning, illing, grinding,

drilling etc. All six working

faces of our plain angle

plates are hand scrapped to

desired accuracy and are

square and right angle to

each other. Fabricated using

high quality closed grain cast

iron of Grade FG-220, these

angle plates comply with IS 2554:1971 standards.

|

|

Box Angle Plates

We specialize in offering

qualitative box angle plates.

These are basically used for

shaping and milling, wherein,

job can be fixed on one of its

faces and are rotated in 5

positions without the need of

repositioning or disturbing

accuracy. Our range of box

angle plates is used in diverse

engineering industries where

all the parameters such as

squareness, flatness and

parallelism are required in a

single instrument. These

parameters are true to each

other for effective functioningof the plates.

|

| --------------------------------------------------------------------------------------------------------------------------------------------------- |

Tolerances on overall deviation from flatness in microns as per International Standard ISO 8512-

2:1990 / Indian Standard 7327:2003 |

| Sizes

L x B x H

mm |

Grade 0

um |

Grade 1

um |

| 400 x 400 x 63 |

4.5 |

9 |

| 630 x 400 x 80 |

5 |

10 |

| 630 x 630 x 80 |

5 |

10 |

| 1000 x 630 x 150 |

6 |

12 |

| 1000 x 1000 x 150 |

7 |

14 |

| 1200 x 900 x 150 |

7 |

14 |

| 1200 x 1200 x 150 |

8 |

16 |

| 1600 x 1000 x 200 |

8 |

16 |

| 2000 x 1000 x 200 |

9.5 |

19 |

|

| --------------------------------------------------------------------------------------------------------------------------------------------------- |

Standard Size and accuracy of Luthra Slotted Angle Plate as per IS 2554:1971 Grade - 1

Specification |

Size in

mm |

Accuracy in Microns

um |

Flatness of

working faces |

Squareness of

working faces

over dimension

H |

Parallelism of

opposite faces &

edges over their

total length |

Squareness of end

faces with respect

to exterior faces as

measured over

dimension L |

| 150 x 100 x 125 |

5 |

10 |

13 |

13 |

| 150 x 150 x 150 |

5 |

10 |

13 |

13 |

| 175 x 100 x 125 |

5 |

13 |

15 |

15 |

| 200 x 150 x 125 |

8 |

15 |

18 |

18 |

| 250 x 150 x 175 |

8 |

15 |

18 |

18 |

| 300 x 200 x 225 |

8 |

18 |

20 |

20 |

| 300 x 300 x 300 |

8 |

18 |

20 |

20 |

| 350 x 200 x 250 |

8 |

18 |

20 |

20 |

| 450 x 300 x 350 |

10 |

18 |

20 |

20 |

| 400x 400 x 400 |

10 |

18 |

20 |

20 |

| 600 x 400 x 450 |

10 |

20 |

23 |

23 |

|

Size in

mm |

Accuracy in Microns

um |

Flatness of

working faces |

Squareness of

working faces

over dimension

H |

Parallelism of

opposite faces &

edges over their

total length |

Squareness of end

faces with respect

to exterior faces as

measured over

dimension L |

| 700 X 420 X 700 |

50 |

140 |

140 |

140 |

| 900 x 600 x 700 |

50 |

140 |

140 |

140 |

| 1000 x 700 x 500 |

50 |

140 |

140 |

140 |

|

| --------------------------------------------------------------------------------------------------------------------------------------------------- |

Tolerances on overall deviation from flatness in microns as per International Standards

ISO 8512-1:1990 / IS: 2285-2003

Cast Iron Surface Plates

Specification |

Sizes

L x B

mm |

Grade 0

um |

Grade 1

um |

Sizes

L x B

inches |

Grade 0

um |

Grade 1

um |

| 250 x 250 |

3.5 |

7 |

12” x 12” |

3.5 |

7 |

| 400 x 400 |

4.5 |

9 |

12” x 18” |

4.5 |

9 |

| 630 x 400 |

5 |

10 |

18” x 18” |

4.5 |

9 |

| 630 x 630 |

5 |

10 |

18” x 24” |

5 |

10 |

| 600 x 750 |

5 |

10 |

24” x 24” |

5 |

10 |

| 1000 x 630 |

6 |

12 |

24” x 30” |

5 |

10 |

| 1000 x 1000 |

7 |

14 |

24” x 36” |

6 |

12 |

| 1200 x 600 |

7 |

14 |

36” x 36” |

7 |

14 |

| 1200 x 900 |

7 |

14 |

36” x 48” |

7 |

14 |

| 1200 x 1200 |

8 |

16 |

|

|

|

| 1000 x 1600 |

8 |

16 |

|

|

|

| 1000 x 2000 |

9.5 |

19 |

|

|

|

| 1200 x 1800 |

9.5 |

19 |

|

|

|

|

| |

| Inside Dial Calipers | Gauge Blocks / Slip Gauges | Surface & Angle Plates |

| Testing Instruments | Magnetic & Nonmagnetic V Blocks | Torque Wrenches | Pistol Calipers | |