Specialized for all types of

Electric, Oil & Gas Fired Furnaces, Industrial

Furnaces, Laboratory Furnaces, Jewellery Furnaces, Ovens,

Refractory Lining & Spare Accessories Etc. |

|

|

Products |

|

|

|

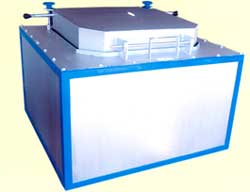

Heating Method :-

Electric.

Max. Temperature :- 900 șC

Control :- Digital / PID. Temperature control

with / without Soak Timer.

Available :- In All Sizes As per Customer

Requirements In Octagonal ,Square & Round

Chamber ,Bel-Type, Pit-Type for BATCH Annealing

With Bottom f & Side Wall mounted Heaters

,Separate Control Panel & Easy and Smooth Hinged

/Lift and Swived type Door. Roller Hearth & Mesh

-,Belt Furnace For Transformer Lamination

Continuous Annealing.

Ideal For:- Transformer Core / Lamination

Annealing, C. T. Core ,Round Core, Rectangular

Toroidal Core Annealing & Amorphous Metal

Annealing.

All kind of Annealing Purpose.

Manually Operated Batch

Continuous Type Furnace. |

| |

|

|

|

|

Heating Method :-

Electric, Oil fired & Gas fired.

Max. Temperature :- 1100 șC

Control :- Digital / PID. Programmable

Temperature Controller.

Available :- In All sizes As per Customer

Requirements With Separate Floor Mounting

Control Panel, With Motorised / Manually

Operated ,Smooth movements of Bogie with Door Or

vertically counter weight Lifting type Door.

Ideal For :- Stress-Relieving ,Annealing

,Hardening, Tempering ,Brass/ Copper Annealing

and Preheating.

|

|

|

|

|

Heating Method :-

Electric, Oil fired & Gas fired. Max.

Temperature :- 1"00 șC.

Control :- Digital / PID. Temperature control

with / without Soak Timer.

Available :- In All sizes As per Customer

Requirements With separate Control Panel,

Silicon Carbide Crucible, Graphite Crucible,

Cast-iron Crucible.

Ideal For:- Led Melting , Brass Melting

,Aluminium Melting & Copper Melting, Manually

Operated Melting I Holding Furnace.

|

| |

|

|

|

|

|

Heating Method

:-Electric , Oil fired & Gas fired. Max.

Temperature:- 1100 șC. Control :- Digital /

PID. / Programmable Temperature Control

Available :- In All sizes As Per Customer

Requirements With separate Control Panel, Front

/ Tope side Loading, Hinged / Vertical (counter

weight Lifting Type Door.

Ideal For :-Annealing , Hardening ,Stress

Reliving ,Normalizing ,Carburizing , Nitriding&

Brigth Hardening, Manually Operated Batch

Type Furnace

|

| |

|

|

|

|

Heating Method :-

Electric, Oil fired & Gas fired.

Max. Temperature:- Pot type furnace :- 1050 șC .

Electrode furnace :- 1250 șC.

Control:- Digital I PID. Temperature controller.

Available :-As per customer requirements in

Round Chamber With Separate Control panel.

Ideal for:- Salt-Bath Hardening, Salt-Bath

Tempering ,Annealing , Liquid Carburing & Pre-

Heating.

|

|

|

Tempering

Furnace |

|

Heating

Method :- Electric .

Max. Temperature :- 750 ºC

Control :- Digital / PID Temperature Control

with / without Soak Timer.

Available :- As Per customer Requirements In

Round & Box Type Chamber, Front / Top side

Loading with Air Circulating Unit ,Hinged / Lift

& Swived / Vertical Lifting type Door & Separate

Control Panel .

Ideal For:- All Kind of Tempering Jobs.

|

|

|

Muffle

Furnace |

|

|

Heating

Method :- Electric

Max. Temperature :- 1200 șC.

Control :- Digital / PID. Temperature Control.

Available :-In All sizes As per Customer

Requirements "With Hinged Type Front side Door

Ideal For :- Laboratories, industrial

Applications, Engineering Tests of soils &

Aggregates cement Testing, Ashing organic and

inorganic Samples, Gravimetric analysis &

Ignition Tests. |

|

|

High

Temperature Furnace |

|

Heating

Method :-Electric .

Max. Temperature :- 1400 șC.& 1600 șC

Control : - Digital / PID / Programmable

Temperature Controller.

Available :- In All sizes As Per Customer

Requirements In Box Type Muffle furnace.

Ideal For: Laboratories Testing & High

Temperature Processing. |

|

|

Continuous Furnace

Heating Method :- Electric & Gas fired.

Max. Temperature :- 300 șC. to 1100 șC.

Control :- Digital / PID. Multi Zone Temperature

Control / Variable Speed Control Panel.

Available :-As per Customer Requirements With

Separate Control Panel. In All Sizes Of :-

Roller- Heath Furnace

Ideal For Heat Treatment / Annealing /

Normalizing of steel With Direct & Atmosphere

Firing.

Conveyorized Furnace.

Ideal For Tempering / Hardening / Annealing &

Sintering of Brass, Copper, Glass & Small / Big

Components. This can be used for Ceramic / Glass

Colour Coating / lnkjet Printing & Decoration.

Sintering Furnace

Ideal For :-Continuous Hardening / Quenching /

Tempering of Bimetal Strips, Wire & Ferrous,

Non-ferrous Components. |

|

|

Rotary Retort Furnace

Heating Method :-Electric, Oil fired & Gas

fired.

Control :- Digital / PID. Temperature Control

with / without Soak Timer .

Available :- As Per Customer Requirements With

Separate Control Panel & Hydraulic / Mechanical

Tilting Arrangement.

Ideal For :- Hardening / Normalizing / Gas

carburizing & Heat Treatment Process of Bearing

ball , Bearing roller , Chain , Chain -links and

other Small components. |

|

| Powder Mixing Machine |

Core Winding Machine |

|

|

|

|

|

|