Disc Springs : |

| |

|

|

Introduction:

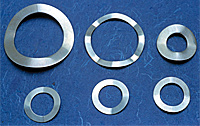

Disc Springs are conically formed

angular Discs, which are loaded in the axial direction.

Disc Springs offer a well-developed solution to many

engineering problems. Through a unique combination of

high force in a small space, Disc Springs can be used as

single disc or arranged in stacks. A spring stack can

consist of either single spring or parallel spring sets.

Disc Springs are available with or without contact

flats. Disc Springs and Belleville Washers are

manufactured to DIN 2093 AND din 6796. We have

computerized design programmed to assist our customers

for their specified applications. Disc Springs are

manufactured from imported 50CrV4 material. Our Disc

Springs are AUSTEMPERED. This method of heat treatment

is particularly effective for springs, as it gives the

maximum toughness and therefore considerable durability.

Advantages of Disc Springs

1. No Deformation or Fatigue under normal loads.

2. High Energy Storage Capacity.

3. Long Service Life.

4. Stock keeping is minimized as the individual spring

sizes can be combined universally.

5. Space Saving.

6. Largely Self-damping, giving good shock absorption

and energy dissipation.

7. Efficient use of space and high spring force with

small deflections.

8. Adaptable to stacking in numerous configurations.

9. Combination use as a modular spring element.

10. Low Maintenance cost

11 Greater Security

|

|

Request a quote

|

Wave Spring Washers : |

| |

|

IIS makes all types of wave Spring washers as per DIN 137 & DIN

6904. IIS Wave washers are made from prime quality spring steel,

stainless steel, copper and other material which are readily

available in very standard sizes. Wave washers are wavy metal

washers designed to offer a compensating spring force and

maintain a load or take up shock. These are the disc of

irregular shape formed in such a way that when loaded it

deflects, acts like a spring, and provides a preload between two

surfaces. Wave washers are very useful for limited radial space

and moderate thrust load e.g. Axial loading of Ball bearing.

The number of waves can be two, three or ~ more. The spring rate

is proportional to the number of waves raised to the fourth

power.

Wave Washers are generally preferred as cushion spacers between

parts on shafts or to take up the probable deviation in

assembled parts. These are positioned underneath a nut, an axle

bearing or a joint to reduce friction, avoid leakage, isolate,

stop loosening or distribute pressure. IIS has ready stock of

all the sizes. For details checkout our website.

|

|

Request a quote

Flapper Reed Valve & Springs : |

| |

|

|

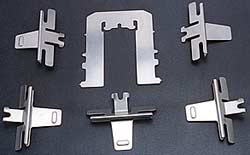

Reed Valve is a Flapper valve steel component used in different

types of compressors for effective control of gas, fuel and air.

Flapper Reed valves must be capable of working continuously for

long periods without failure. A careful & controlled

manufacturing process is essential for the proper function &

longer service life of a Flapper Reed Valve.

Flapper valves are used In :

1. Refrigerators 2. Air Conditioners 3. Freezers

4. Heat Pumps 5. Brake Systems 6. Vacuum Pumps

7. Industrial Air Compressors

Material :

Material used for Reed valves are 20C, 7C27M02 & Hiflex This

material is purchased form Sandvik Materials Technology

|

Stampings and sheet metal : |

| |

|

IIS has all the facilities to handle large

volumes of stampings & sheet metal components. We have automatic

decoilers & feeders & high speed heat treatment furnace for

faster production. We can stamp upto thickness of 10mm or 0.4"

We have a production capacity of 25MT tons per month for one

shift.

WE can supply OEM quality stampings with flatness and tolerance

on dimension in microns

IIS can make stamping from various materials Stainless steel,

Carbon Steel, Spring Steel, Precipitated hardened Stainless

Steel, High Temperature & other Exotic Materials.

We have in house tool room to develop urgent tools & dies.

We can develop prototypes & samples for your R & D requirements.

Our high speed deburring machines help in giving rounded and

burr free edges for all type of stampings.

|

| Request a quote |

|

| |

|

|

Website :

www.discspringsindia.com

,

www.bellevillewashersindia.com

,

www.lockritewasher.com

,

www.internationalsprings.com

|

|

|

|