|

|

The Wonderful Building Material

Of The World

Manufactured in India since 1972, in collaboration with International

Siporex

AB of Sweden. The unique flexibility, structural and physical properties of

Siporex (ALC - "Aerated Light Weight Concrete) are appreciated the world

over and is the preferred building material. It is ideal for all types of

climatic and seismic zones |

|

Aerated Light Weight concrete is today recognized the world over as an

environment friendly product due to its superior

insulating and energy saving

properties. Increased use of Siporex helps to conserve and protect our planet's

forest cover.

Siporex is structural material, steam cured, cellular (aerated) concrete. It

is available as blocks, floor and

roof slabs and wall panels, for all types of

buildings Specially for multi-storeyed buildings

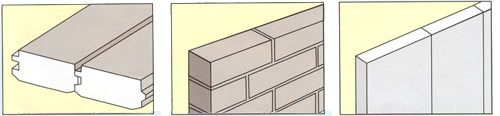

Roof and Floor Slabs

Available in lengths of 1 Mtr. to 5 Mtrs. in increments of 0.5 Mtr. and thickness from 100 mm to 200 mm, depending

upon super-imposed loads and spans

Building Blocks

Available Sizes :

200 x 240 x 600 mm

150 x 240 x 600 mm

125 x 240 x 600 mm

100 x 240 x 600 mm

Partition Walls

Panels available in lengths of 1.5 Mtr. to 3.0 Mtr. in increments of 0.5 Mtr.

and thickness from 75 mm to

100 mm

Properties of SIPOREX |

|

Light Weight : Oven dry density of SIPOREX is 450

to 650 kg/m³ i.e. just one fourth the weight of dense of dense concrete, thus ensuring

economic design. It also makes SIPOREX ideal for low bearing soils, for seismic

zones and for adding storeys to existing buildings. It is easy to handle, hoist

and transport. It is the ideal material for use in existing buildings where

additional FSI/TDR is available. |

|

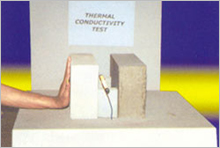

Highly Insulating : Cuts the peaks of heat and

cold to provide economy in the working of air conditioning

and central heating.

K value 0.122 Kcal/ Hr/ M° C makes it suitable as insulation material for

boilers, heat

exchangers, furnaces, ovens, forges, steel works, galvanising kettle linings,

etc. saves 25% cost of

installations as well as recurring costs of electricity |

|

|

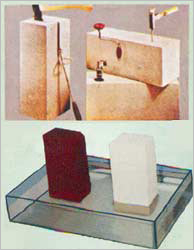

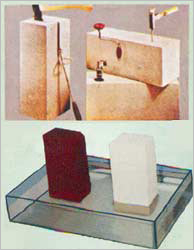

Fire resistant & incombustible : SIPOREX which is completely inorganic , is totally incombustible and offers twice

protection of concrete. It is ideal for fire walls and fire protection of

structural steel. SIPOREX has been tested for fire

resistance at CBRI, Roorkee.

Their conclusions are as follows

SIPOREX ROOF SLABS

The data of evolution and their analysis reveal that the roof of the Siporex roof

slabs was able to withstand

the standard fire for 150 minutes under uniform load

320 kg/m² as per IS:3809, BS: 476 part 20 and

ISO 834

SIPROEX WALL PANELS

The data of evaluation reveal that the partition wall of Siproex wall panels was

able to withstand the standard fire for

180 minutes as per IS: 3809, BS:476 Part

20 and ISO 834

SIPOREX LOAD BEARING BLOCKS

The data evaluation reveal that the wall of Siporex load bearing blocks was able

to withstand the standard fir 240

minutes under uniform compressive load 15

kg/m² as per IS:3809, BS:476 Part20 and ISO 834 |

|

High strength to weight ratio

For SIPROEX 18 to 22 against 16 for concrete of M 150 grade

Water Penetration

SIPOREX structure being of closed cells, there is less capillary action and

high surface activity allows for last evaporation of moisture.

Water Repellant

While manufacturing reinforced SIPOREX slabs, silicon oil is added in wet

mass which makes the product water repellant

Comfortably worked

SIPOREX is versatile. It can be drilled, chased or nailed using simple

carpentry tools. Thus, it simplifies plumbing,

electric work, fixing joinery,

etc. preventing wastages at site. SIPOREX is workable like wood and endures like

stone |

|

Sound Absorption

Sound absorbency of air borne sound for 3" and 4" walls is 38 to

40 db, thus absorbency of air borne sound for 8"

thick walls gives an

increase of 45 db. Hence, ideal for auditoriums and theatres and for cutting off

workshop sounds

from offices

Corrosion Resistant

Reinforcement bars used in SIPOREX slabs and wall panels re treated with a

patented, highly effective, anti- corrosive

treatment which has been evaluated

for CBRI, Roorkey, with recommendation that "Protective Coating" (two

coats of

ACM and one coat of inertol) applied by Siporex India Ltd. is highly

satisfactory for preventing corrosion of M.S.

reinforcement is Siporex concrete in coastal and highly polluted areas like Mumbai" Also, silicon oil is used

during

production to make the slabs water repellant

Environment Friendly

By indiscriminately cutting down our forests, natural disasters are rapidly

increasing. SIPOREX eliminates

use of timber

and thus helps to conserve our forests. SIPOREX also eliminates

the use of bricks which consume valuable fertile soil

required to grow food for

our vast population. |

| Enquiry :- |

* Indicates Compulsory Fields |

|

|

|

|

|