|

|

| |

|

|

|

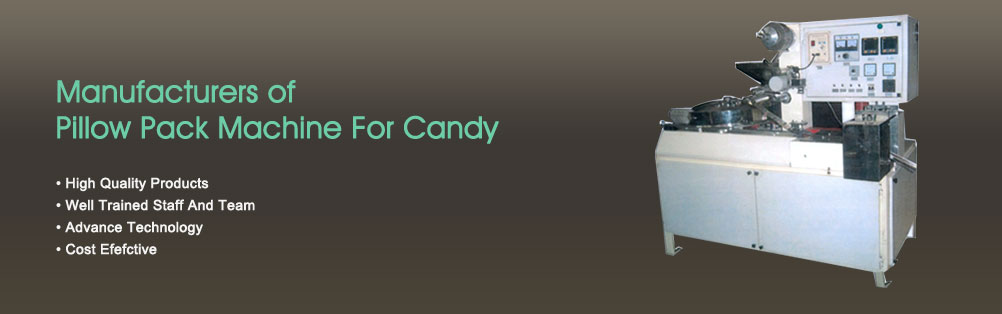

| Hard Boiled Candy Horizontal Pillow Pack Wrapping Machine |

|

| This fully automatic machine packs small products into waterproof airtight single or multiple packs. |

|

| |

|

|

|

| Technical Data : |

|

| Output : Up to 800 to 1000 packs/min depending open the product and it's packing material |

|

| Electrical Load : 12 AMP, 1 H.P. motor with vibrator and Heater Brush machine can be connected to single phase. |

|

| Weight : Approximate weight 970 Kgs with vibratory feed feeder, changeable, candy feeding disc, Lug conveyor, sealing roller, cross sealer and last chute. |

|

| |

|

|

|

| Space Required : 1600 Height x 1700 width x 2000 mm long. |

|

|

|

| |

|

| Method of Operation : |

|

| The vibatory feeder takes the candies from SS hopper, the chute removes the dust and broken pieces and feeds the desired candies to the disc. This detachable disc has the precise shape of the candies which goes to the lug conveyor. The Tapping material is released from the reel feed unit, passes through the rollers. Then the photo-cell mark is constantly monitored. The film a continuous tube in which the lug conveyor positions the candies. This continuous tube is sealed and guided by two pairs of sealing and pulling Rollers. |

|

| The cross sealers seals the individual packs and having zig zag knife fixed inside he cross sealer, seperates the individual pack or gives perfection as desired. |

|

| |

|

| Each pack is thus scanned allowing a greater tolerance for adjustment of cut-off length. |

|

| |

|

| Wrapping Material to be used. |

|

| Printed or unprinted reels with a core bore of 75 mm and outer dia. of the reel to be 300 mm heat scalable packing |

|

| |

|