Pneumatic Conveying System

|

|

Pneumatic conveying systems are simple and eminently suitable for transport of powdered and granular materials in factories and chemical plants. Pneumatic conveying systems have a lower initial costs, but higher running costs. The higher running costs are offset by certain unique advantages like contamination free operation, overall cleanliness, free of atmospheric dusting, which reduces health hazards. Certain materials which are degraded when exposed to oxygen in air can be handled with a closed loop pneumatic conveying system. For hygroscopic materials dry air can be use a Systems can be designed such that no material comes in content with any moving parts. |

Materials can be conveyed from a hopper or silo in one location to other location which is some distance away, at a higher elevation where many hurdles makes it difficult to transport the product in a straight line. In pneumatic conveying system there is a lot of flexibility in layout and operation such that multiple point feeding can be made in to a common line and a single line can be discharge in to different receiving vessels. Any material stored in a large heap or stock pile can be handled with vacuum system which makes it suitable also for clearing accumulated dust and spillages. The conveying lines can run horizontally as well as vertically upwards and downwards with long radius bends in suitable combinations. |

| -------------------------------------------------------------------------------------------------------------------------------------------------------------------- |

|

|

Unique Features:-

Silo is a storage vessel for free flowing powders and granules. They are used either to store bulk raw-material received from market till it is use in production or to store finished material till it is packed in suitable containers or bags in different size of packing. Entec makes Silos as small as 5 m3 up to 500 m3 to store different materials. The silos can be located outside the plant building, open to atmosphere without any possibility of rain water or atmospheric dust contemning the product Silos can be mounted on load cells to monitor the weight of the material stored.

When used in conjunction with Pneumatic Conveying System, multiple silos can be filled with a single system. Silos can be emptied by means of pneumatic conveying system or with different feeders either to feed hoppers or materials can be packed from silos. Entec silos are designed confirming to DIN-1055. Entec Silos ensures a mass flow discharge i.e. the first in first out basis. (See animation) If the silos are desired to store powders then a suitable vent filter is installed on the roof of the silos.

Entec also provides the necessary ladder & platform to access the roof as well as other attachments like level switches weight indicators & samplers. Silos can be made out off stainless steel, carbon steel & aluminium. |

|

| -------------------------------------------------------------------------------------------------------------------------------------------------------------------- |

|

|

Unique Features:-

|

Very low leakage enables high operating efficiency. |

|

Special arrangement for venting the leakage air there by no difficulty in handling low density material |

|

Special sealing arrangement ensures dust proof working, high shaft life, noiseless operation, no outboard bearings, hence no gland packing. Which reduces maintenance & increase shaft life. |

|

Special inlet port arrangement for pellets operation (on order) for very friable materials where particle degradation poses a problem special offset rotary air locks can be supplied. (See animation) |

|

Only rotary air lock in the market employing axial scene. |

|

For fine powdery material purge air arrangement prevents fine dust entering the bearings. |

|

Life time lubricated bearings. |

|

Dually fitted with geared motor & chain drive. |

|

Available in aluminium, Stainless steel & cast steels body with stainless steel Rotars. |

|

|

| -------------------------------------------------------------------------------------------------------------------------------------------------------------------- |

|

|

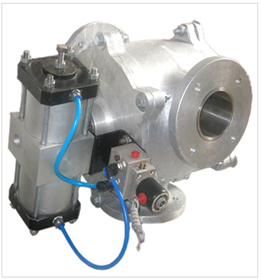

Unique Features:-

|

Entec plug diverter valves are absolute dust free. |

|

Body & Plug made out of LM4, aluminium alloy casting. |

|

Pneumatic rotary actuator insures long maintenance free-life. |

|

S.S.304 tunnel for plug. |

|

Nozzles available with S.S. sleeves. |

|

Dually fitted with non contact type proximity switches. |

|

Life time lubricated bearings. |

|

Special peripherals seals make it highly suitable for fine powders. |

|

No dead pockets which insures zero contamination. |

|

|

| |