| |

Corona Treater for Monolayer Extruders |

|

| |

|

|

| |

Narrow web treater are mainly used for extrusion film plant for small to wide web width and low speed.

Benefits :

- Compact simple construction

- Ultra high frequency

- Soft start

- Low maintenance

- Improved costs savings

- Maximum operator safety

- Easy to install

- Accurate output power

- Economical design

|

|

Economical Corona Treater Generator

|

|

|

| |

|

Top |

| |

Metallized Treater |

|

| |

|

|

| |

Corona treatment for conductive material :

Eltech metallized treater assembly for high-speed corona treatment of conductive as well as non-conductive having smaller widths up to about 500 mm.

These treaters are an extension of suitable to treat conductive as well as nonconductive substrates such as aluminum foils, metallized films, multi layer films, paper, labels of various types etc. |

|

Metallized Treater Assembly

|

|

|

| |

|

Top |

| |

In-mould foil charger (Static Charger) |

|

| |

|

|

| |

We offer superior quality static chargers that can be used to stick PP / BOPP / polystyrene foil material to the inner mold surface during injection molding. This makes the foil constant in a position in the mold due to charging. These static chargers are manufactured in compliance with international quality & safety standards.

Introduction :

In-mold decorating is a process for labeling or decorating a plastic object during the plastic injection molding process. In the in-mold labeling process, a label or appliqué is placed in the open mold and held in the desired position by vacuum ports, electrostatic attraction or other appropriate means. The mold closes and molten plastic resin is extruded or injected into the mold where it conforms to the shape of the object. The hot plastic envelopes the label, making it an integral part of the molded object. The difference between glue applied labels and in-mold labels is that a glue applied label is stuck "on" the surface of the plastic object; the in-mold label is embedded "in" the wall of the object. |

|

Static Charger Power Unit

|

|

|

| |

|

Top |

| |

Power Units |

|

| |

|

|

| |

The Eltech 331 power unit is the most important of different Eltech's static control equipment. The instrument produces high voltage, low current in a controlled and safe manner. It's compact size and structure is suitable for most industrial environments. The defect free products and quality ensures efficient use and maximum customer satisfaction.

We have designed the Eltech 331 power supply and the different discharge bars for active discharging of disruptive static charges, which develop during the production processes. The discharge bars and the power supply are used primarily in cases where disruptive static charges on fast moving material webs impair production processes and required to be eliminated.

|

|

Eltech-335 Power Unit

|

|

|

| |

|

Top |

| |

Shock less Electrodes |

|

| |

|

|

| |

The emitter points of a shock-less static eliminator receive high voltage indirectly. If someone touches the ionizing points, he will feel only a minor tingling sensation. The ionized field is most intensely closed to the emitter pins. The best distance for good static neutralization is between 10 mm to 20 mm. |

|

Shock less Electrodes

|

|

|

| |

|

Top |

| |

Induction Cap Sealer |

|

| |

|

|

| |

Induction sealing is a non-contact process, which is used to bond a foil disk or to seal the opening of a container. The technique provides the user with a tamper evident seal. The seal assures product integrity and prevent any chances of leakage. It increase the products shelf life, reduce pilferage, and ensures maximum customer satisfaction.

Wad :

Wad's are innerseal materials, which are available in different variations to meet almost any standard or customized packaging need. Modifications can be made to suit the types of container, closure and product. There is almost no limit to the size of container, the Wad's can seal. The typical induction innerseal begins with a multi-laminate liner inside a closure. It is made up of following layers :

- A layer of pulp board

- A layer of wax

- Aluminium foil

- A layer of polymer (Heat sealable film)

|

|

Induction Cap Sealer

|

|

|

| |

|

Top |

| |

OZONE Purification |

|

| |

|

|

| |

Ozone is the solution to kill all germs to give you a fresh, healthy, vivifying air !

Ozone is the fastest acting oxidizing disinfectant and the most efficient broad spectrum micro biological control agent commercially available. Being highly reactive and completely non-discriminating it immediately starts oxidizing anything it comes in contact with air. This makes Ozone a very powerful bactericide agent.

Ozone as unlike any other oxidizing agent leaves no toxic residues, thereby environment friendly, and helps in reducing pollution.Ozone, triatomic Oxygen, is colourless gas with a acrid odour. It is very reactive and strongest commercially available sanitizer and decomposes back to oxygen without leaving a trail behind, this makes it the preferred choice for air disinfection and major contribution towards a cleaner environment. |

|

OZONE Purification

|

|

|

| |

|

Top |

| |

Drinking water Purification |

|

| |

|

|

| |

Ozonation is one of the method to convert impure water into to pure drinking water ,ozone inactivares and destroys all bacteria,virus and protozoa’s. Ozone will oxidise both organic and inorganic substances, remove unwanted taste, odour and color, and provide effective disinfection.

Advantages :

- Most powerful oxidizer available

- improves flocculation of iron

- Increases the shelf life of bottled water.

- Produces safe & bacteria-free drinking water.

- Removes heavy metals & cyanides from water.

- Been used for decades

- Iron and manganese removal

- No harmful by-products

- Environmentally friendly

|

|

Drinking water Purification

|

|

|

| |

|

Top |

| |

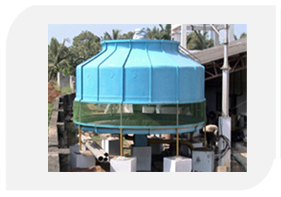

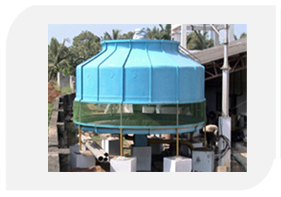

Cooling tower |

|

| |

|

|

| |

Ozone as a cooling tower biocide is not only environmentally benign, it also brings a significant number of other benefits.

The circulating water of cooling tower systems has always been an ideal place for growth of microorganisms. The warm temperature of the water and the addition of nutrients from the scrubbed air flowing through the tower provide a virtual nirvana for all sorts of microbes and algae. In turn, these organisms multiply at fantastic rates. The result is degraded system efficiency due to blockage of flow, shortened equipment life due to corrosion, increased operating cost due to higher pumping power requirements, and the spread of disease or even death.

Ozone as a cooling tower biocide offers a means to this end. It is not only environmentally benign, but ozone use also brings a significant number of other benefits to the cooling tower system operator. Ozone is a practical oxidizing biocide because it is the fastest acting and the most efficient oxidizing agent against all microbiological organisms - when properly applied, ozone will kill all viruses, bacterium, cysts, and algal species. |

|

Cooling tower

|

|

|

| |

|

Top |

| |

Pharmaceutical Process Water |

|

| |

|

|

| |

The Demineralised Water (DM) contains a lot of bacteria which need to be removed before the water is used for the manufacturing of drugs. This

contamination can be effectively removed by ozone.

Ozone for process water disinfection

Why process water disinfection is necessary ?

The process water is used for adding into the product ,Washing,,cleaning of the raw materials and the processing equipment.The microbiological quality of the process water in a food processing factory ,Dairy or a Bakery is of prime importance.The process water should be free from any Bacteria,Yeast,Mouldsor any viruses for production of quality product.

In case the process water is infected ,micro-biological counts of the product will be higher than stipulated and as these micro-organisams grow at a very fast rate,it will adversely affect on the quality of the product ,with respect of preserving freshness and shelf life.

What is the present practice ?

Generally chlorine and other chemicals are added to the process water for the purpose of disinfection .The process water using chemicals leaves harmful by-products after disinfection process e.g.chloramines & trihalomethanes etc. which is not only undesirable but use of chemicals is also banned in some applications and the use of chemicals is being phased out fast.

How ozone can be used for disinfection of process water?

Ozone is very strong oxidizer and a powerful disinfecting property .A very small concentration of ozone in water makes it free from bacteria,virus and pathogens much faster and with lesser concentration in a most effective manner.

What is ozone ?

Ozone,triatomic oxygen ,is colourless gas with an acrid odour .It is very reactive and strongest commercially available disinfectant and decomposes back to oxygen ,this makes it the preferred choice for disinfection of process water and major contribution towards a cleaner environment.

|

|

| |

|

Top |

|