|

|

|

|

| |

TEFC Motors |

| |

|

|

ENERGY EFFICIENT MOTORS LEVEL 2 |

|

| |

|

| |

Energy Efficiency level

2 as per IS:12615 |

| |

Energy Efficiency as

per CEMEP Standards prevalent in Europe |

| |

'V' seal arrangement up

to 355 frame - Easier assembly of bearing housing |

| |

Integral bearing cover

with endshield up to 225 frame |

| |

Larger terminal box for

accommodating bigger Aluminium cables |

| |

Sophisticated CNC

Machines, Most

Advanced Manufacturing Technology &

Test Plant - Improved reliability. |

|

| |

STANDARD

SPECIFICATIONS

| |

|

| RANGE |

0.18 kW

to 400 kW (FRAME 63 to 400)

Multi speed options are also available |

| VOLTAGE |

415 V +/- 10 % |

| FREQUENCY |

50 Hz +/- 5 % |

| COMBINED VARIATION |

+/- 10 % (ABSOLUTE

SUM) |

| INSULATION |

Class 'F' (Temp. rise

limited to class 'B' ) as standard |

| AMBIENT /

TEMPERATURE RISE |

50 0C / 70

0C |

| DEGREE OF PROTECTION |

IP55 AS PER IS: 4691 |

| |

|

|

| |

SPECIAL

DESIGNS OFFERED

|

ELECTRICAL |

MECHANICAL |

| Non

Standard Voltage And Frequency Variation |

Non

Standard Mounting Dimensions |

Duel

Voltage

Triple Voltage |

|

Special shaft

Extension |

Inverter

fed Supplies And AC Variable Speed

drives |

Double shaft

Extension |

| Energy

Efficient Motors |

Low Vibration & Noise

Level |

| High Slip

Motors |

Shock Grade Motors |

Motors

For Frequent starts/stops/reversals

(e.g. crane duty) |

Motors for Hazardous

areas |

| Torque

Motors |

Motors For Dust Laden

Atmosphere |

| High

Frequency Motors |

Brake Motors |

| Textiles

Motors |

Canopy for horizontal

mounting motors |

|

10,12,16,18,24,32 Pole Motors |

Special Bearings like

Thrust Bearings |

| Special

Performance Requirements |

Tacho Mounting |

| Class H

insulated Motors |

Non Standard Paint

Shade and Painting Procedure for

required Dry Film Thickness |

| Motors

With Service Factor |

Fabricated Steel

Enclosure

Alternate Terminal Box Position |

Slipring

Motors with Bar-wound rotors for

Frames 280 to 400 |

Special Shaft

Material |

Motors

for operation on Variable Frequency

Drive - Refer note on next Pages |

Stainless Steel/

Brass Hardware

Accessories like Resistance Temperature

Detectors,

Bearing Temperature Detectors, Thermocouples,

Plug

& Socket |

| |

Custom Size

Fabricated terminal box & Terminal

Arrangements. |

|

|

|

| |

Top |

|

|

| |

Energy

Efficient Motors |

| |

|

|

ENERGY EFFICIENT MOTORS LEVEL 1 |

|

| |

Crompton Greaves has

now developed a complete family of high efficiency

motors confirming to Eff level 1 standards of IEEMA

: 19-2000 and other applicable standards in Europe

and rest of the world.

These motors are available in TEFC

construction for use in safe areas and also in

flameproof enclosure for use in Hazardous areas. |

| |

|

|

SPECIAL DESIGN FEATURES : |

| |

Higher efficiencies are

achieved by following special features :

• Low loss special grade of thinner laminations.

This reduces the Iron loss even at partial loads.

• Thicker conductors and more copper contents

reduce copper loss due to lower resistance.

• Longer core length, reduced and uniform air gap

between stator and rotor to reduce stray losses .

• Special design of fan and fan cover to reduce

windage losses. |

| |

|

|

BENEFITS : |

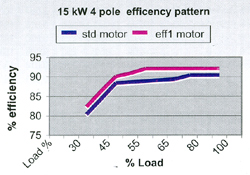

Improved efficiency is available from 60 % to

100 % load. The eff curve is almost flat

resulting in higher energy savings as in most of

the cases the motor is not always fully loaded .

The special design features also result in lower

operating temperatures which enhance the life of

motor and reduce the maintenance costs.

These motors have inherently low noise and

vibration and help in conservation of

environment . Crompton Greaves energy efficient

motors offer an additional feature which no

other manufacturer offers.

These motors are with highest power factor in

the industry due the special exclusive designs

available with Crompton Greaves.

The higher power factor reduces the currents in

the cables supplying power to motor and this

reduces cable loss, improving the system

efficiency sometimes by even 2 %.

Sometimes this allows even a lower cable size

saving tremendously on capital costs. Saving is

also made by reducing capacitors required to

improve power factor. |

| |

|

MANUFACTURING RANGE : |

Efficiency Level 1

• 0.37 kW to 160 kW

• Frame sizes : 71 to 315 for TEFC 80 to 315 for

Flame proof

• The entire range is available in IEC frames

sizes (metric range) and also in NEMA frames |

|

| |

CONFORM TO

FOLLOWING STANDARDS :

• IEEMA : 19-2000

• IS 12615

• IS 325-1996 & IEC 60034

• NEMA EPACT EFFICIENCY VALUES (for NEMA motors)

IEEMA 19-2000 standard covers kW ratings only up to

160kW. However we are offering energy efficient motors

up to 450 kW. |

| |

IMPORTANCE OF

ENERGY EFFICIENCY :

|

Growing cost of energy calls for power saving at

each possible step of manufacturing. Electric

motor driven systems used in industrial

processes consume more than 70 percent of

electricity used in industry, hence best

possible technology is being applied for

achieving highest possible efficiency values. |

|

| |

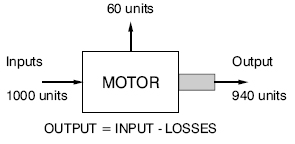

EFFICIENCY MEASUREMENT OF AN ELECTRIC MOTOR

The efficiency of an electric motor is

determined by the amount of useful power it

produces compared to the amount of energy

required to operate it. The figure below

illustrates how a Crompton Greaves Energy

efficient motor effectively turns 1000 units of

electrical power into mechanical power.

Since motor efficiency is commonly expressed as

a percentage. Efficiency in this case would be

94%. |

|

| |

|

|

ENERGY EFFICIENT MOTORS LEVEL 1 |

|

|

The benefits of using these motors are maximum in

continuous duty applications like Blowers,

Compressors, Fans, Exhausters Pumps etc. |

| |

|

|

BEST PERFORMANCE EVEN AT PARTIAL LOADS : |

|

|

In many applications the load factor of the motor

will range between 60% to 80%. The efficiency curve

of standard motor is drooping in nature i.e there is

a sharp fall in efficiency at partial loads. But the

energy efficient motors have a flat efficiency curve

and hence the fall in efficiency is marginal. Thus

energy saving is significant even in part loads. |

| |

|

|

| |

|

| |

INTERNATIONAL APPROVALS CERTIFICATES

|

| |

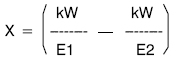

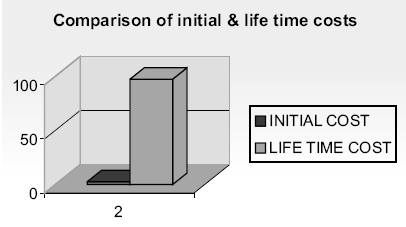

ASSESSING COST EFFECTIVENESS OF ENERGY EFFICIENT MOTORS

:

Savings :

Savings are calculated as follows :-

kW - out put of motor in kW

E1 - efficiency of standard motor

E2 - efficiency of energy efficient motor

|

Savings=X * |

|

|

|

| |

EXAMPLE

3.7 kW

4 pole motor in frame ND112M

Std motor eff 2: 85 % eff1 88.3 %

Price eff2 : Rs 7215/- eff1: Rs 9380/-

Working hours 16 per day, working days 300 in a

year,

power rate Rs 4.50 per kWH

X = 0.1626

RS Savings = 0.1626X16X300X4.5

= 3514 /- RS per year

Extra investment RS 2615/-

Payback period = 9 months

Energy cost for a 15 years usage at Rs 4.50 /

kWH is staggering 14.10

lacs as compared to buying cost of Rs 7215/-.

Also the energy kWH rate

is likely to only go up in future.

If we compare initial purchase price of the

motor with the cost of energy

it uses over it working lifetime, the initial

cost represents less than two

percent of its lifetime cost in most of the

cases . |

So it makes a great deal of

sense to choose an eff1 level motor whenever

a motor is needed to drive any applications.

Combining this with usual Crompton greaves

motors reliability, wide service network

(over 180 service points all over India),

the wise choice is Crompton greaves EFF1

motor. |

|

| |

Top |

|

|

| |

Flame Proof

Motors |

| |

|

|

THE WIDEST AVAILABLE RANGE |

|

| |

SQUIRREL

CAGE MOTORS

0.37 kw to 355 kw (Frames E80 toE355 LX)

SLIP RING MOTORS

22 kw to 160 kw

(Frames EW 250 M to EW 315 L) |

| |

|

|

STANDARD SPECIFICATIONS |

| |

VOLTAGE :

415 ± 10% Other Voltage class

(220 V - 660 V) available on request. |

FREQUENCY :

50 ± 5% 25 HZ to 60 HZ available on request. |

Combined variation :

± 10 % (absolute sum) |

INSULATION :

Class F Class 'H' can be given on request. |

RATING/DUTY :

Continuous (S1) Intermittent duties

available on request. |

MOUNTING :

Horizontal foot mounting (B3)

Other mountings available on request. |

PAINT :

Epoxy anticorrosive painted surface

(Standard shade 631 as per IS - 5) |

AMBIENT / TEMPERATURE RISE :

450C/750C. Higher Amb.

upto 600C on request. |

TEMPERATURE CLASS :

T4 |

DEGREE OF PROTECTION :

IP 54 - E80 - E132 M

E225 M to E355 LX

(IP55 with canopy can be offered.)

IP55 - Frame E 160L to E 200 L. |

|

ERTL / CCOE (PESO) / DGMS approvals as a

standard feature. For BASEEFA approval

please contact nearest branch office/works. |

|

|

| |

|

|

| |

APPLICABLE

STANDARDS :

|

Enclosure |

IS 2148 EN 50018 |

| Performance |

IS325 BS 5000 (Part

10) IEC60034 -1 |

| Performance for

Mines |

IS 3682 |

| Dimensions Foot |

IS 1231 IEC60072-1 |

| Flange |

IS2223 BS4999 Part 414 |

|

| |

INDUSTRIAL

APPLICATIONS :

|

• Coal Mines. |

• Petro Chemicals & Chemicals. |

|

• Oil Mines & Rigs. |

• Fertilizers. |

|

• Solvent extraction plants. |

• Paints & Varnish Industry. |

|

• LPG Bottling plants. |

• Agro Chemicals. |

|

• Drugs & Pharmaceuticals. |

• General Industry. |

|

| |

SPECIAL

PURPOSE MOTORS FOR

|

1. Longwall mining equipment. |

|

2. High pressure mine ventilation fans with plug

& socket arrangement. |

| 3.

Auxiliary mine ventilation fans with rod

mounting / flange mounting. |

|

4. Belt

conveyors and armoured face/ chain conveyors. |

| 5. Side

dump loaders, load haul dumpers |

|

6.

Haulages (squirel cage and slipring motors). |

| 7.

Dewatering pumps. |

|

8.

Sucker rod pumps. |

| 9. Mud

agitators & mud pumps. |

|

10.

Slurry extraction pumps. |

| 11. Air

compressors & blowers. |

|

|

|

| |

SPECIAL

DESIGN FEATURES AVAILABLE

|

1. Dual voltage (550/1100V) with 9 terminal

connections as per NCB 625 |

|

2. Non standard voltage and frequency variation |

3. Dual voltage (1:2 or 1: ratio) Tripple voltage (1:

ratio) Tripple voltage (1: : 2 ratio)

: 2 ratio) |

|

4.

Energy efficient motors High slip motors Motors

for frequent starts/stops/reversals |

| 5.

10,12,16,18,24,32 pole motors |

|

6.

Special performance requirements |

| 7.

Class H insulated motors |

|

8. Low

vibration and noise level |

| 9.

Special Bearings |

|

10.

Tacho mounting |

| 11.

Special shaft material |

|

12.

Canopy |

13.

Plug & socket arrangement (30 to 300 Amps, 650 &

1100V) for

underground equipments. |

|

15.

Special RV/RA for slipring motors. |

| 16.

Space heaters, thermisters. |

|

17.

Multispeed motors. |

| 18.

Double /taper/non standard shaft extention |

|

19. Non

standard paint shade |

| 20.

Motors for use with variable frequency inverter

supply |

|

|

|

| |

TERMINAL

BOX AND TERMINAL ARRANGEMENT

|

• Cast iron construction, forming a separate

flame proof enclosure capable of containing

internal explosions |

|

• Standard position on right hand side viewed

from driving end side except in frames E 80,

E/EW 315 L & E 355 LX where it is on top. |

|

• Terminal box on top on specific request. |

|

• New

terminal box with spigotted cover & gland

plate/sealing box in frames E 160 to 355 LX with

following advantages |

|

• Inherently IP 55. |

|

• Spaciously designed for accommodating bigger

cables. |

|

• Double decker terminal arrangement for easy

termination of two cables. |

|

• Anti

loosening terminal arrangement |

| • For

slipring motors, separate terminal box for

stator & rotor terminations provided. Stator

terminal box is on left hand side while rotor

terminal box is on right hand side, viewed from

driving end. |

|

• Conduit plate is provided as standard while

sealing box provided for

group I gases. |

|

• Separate terminal box for auxiliary terminals

(space heaters, thermisters) for frame 225 and

above on request. |

|

|

|

| |

TERMINAL STUD

|

• Fully non hygroscopic thermosetting moulded

glass filled compound. |

|

• Increased clearances & creepages. |

|

• Anti loosening arrangement. |

|

• Metallic bush insert to take tightening

pressure. Eliminates breakage of insulation

(E160-315LX frames) |

|

| |

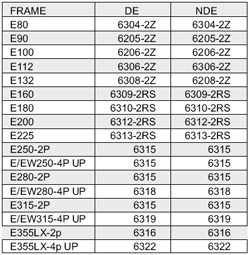

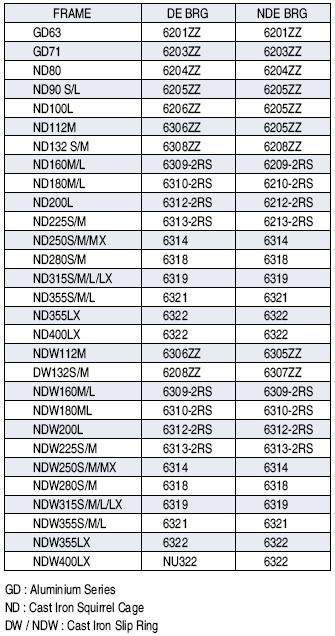

BEARING CHART :

|

| |

|

BEARING CHART : |

|

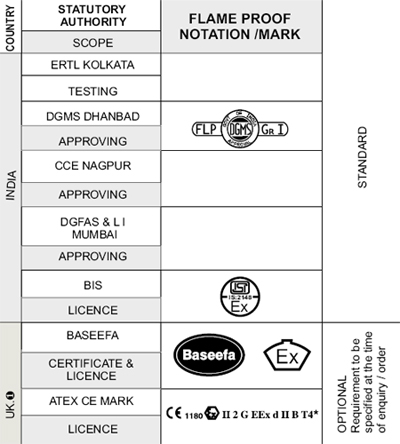

STATUTORY APPROVALS : |

|

|

|

|

| |

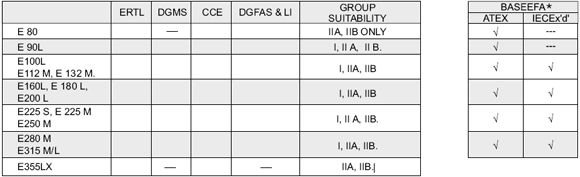

FLAMEPROOF MOTORS FOR GROUP IIC ATMOSPHERE

A complete range of Crompton

Greaves flameproof squirrel cage motors for gas group

IIC is now available for Indian Industries as an import

substitute. The motors are manufactured as per the most

stringent requirements for IIC atmosphere. The motors

are duly tested at ERTL. For more details, please

contact our nearest branch office / works.

AVAILABLE Pending for approval.

* STANDARD Temperature class T4. Other classes

available on request. * For IIA, IIB Gas Groups |

| |

|

CMRI |

: |

CENTRAL MINING RESEARCH INSTITUTE, DHANBAD. |

| DGMS |

: |

DIRECTORATE GENERAL OF

MINES SAFETY, DHANBAD. |

| CCE |

: |

CHIEF CONTROLLER OF

EXPLOSIVES, NAGPUR. |

| DGFAS & LI |

: |

DIRECTORATE GENERAL

FACTORY ADVICE SERVICE & LABOUR INSTITUTE, MUMBAI. |

| BIS |

: |

BUREAU OF INDIAN

STANDARDS, NEW DELHI. |

| BASEEFA |

: |

BRITISH APPROVALS

SERVICE FOR ELECTRICAL EQUIPMENT IN FLAMMABLE

ATMOSPHERES, UK. |

| ATEX |

: |

EUROPEAN DIRECTIVE |

| ERTL |

: |

ELECTRONIC REGIONAL

TEST LABORATORY |

NOTE:* Motors as per UK based standards can

be supplied against specific enquiries. |

| |

Top |

|

|

| |

Crane Duty Motors |

| |

|

APPLICATION : |

|

Prabal series squirrel cage/slip ring Crane duty

motors are specially designed for service on

cranes and hoists. They can also be used for

similar applications such as material handling

equipments, and cranes of all types. These

motors can serve as auxiliary motors in rolling

mills or wherever intermittent duty drives are

required.

These are duty type rated

motors developing high starting torque with

low starting current. The motors are

suitable for frequent starts/ stops and

reversals. Also rapid acceleration is

achieved by high pull out torquelrotor

inertia ratio. |

|

| |

TYPICAL APPLICATIONS :

Crane duty motors are

used for following applications in majority: Cranes

& hoists: long travel drive, cross travel drive,

main hoist, auxiliary hoist. Material handling

equipments: various conveyors Lifts Rolling mills |

| |

RANGE :

Manufacturing range for

cast iron slip ring crane duty motors is from 112 to

400 frame. The same for squirrel cage motors in cast

iron enclosure is from 80-400 & in aluminium

enclosure is from 63-160.

|

| |

MOUNTING :

Squirrel cage crane duty

motors are supplied with horizontal foot- mounting.

However, motors suitable for foot / flange / face

mounting or any combination of these with vertical

or horizontal orientation can be offered when

required. Slip ring motors are normally available

with foot mounting Flange mounting can be supplied

on specific request. |

| |

POWER

SUPPLY :

Crane duty motors are

suitable for 3 phase supply and can be wound for

any single voltage from 220 to 650 volts and

frequencies from 50 Hz or 60 Hz. The rotor

voltage is committed for stator supply of 415 V,

50 HZ.For other supply conditions, Rv to be

confirmed from CG. |

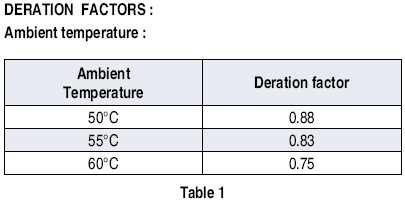

AMBIENT TEMPERATURE :

The motors are rated at 45°C ambient

temperature. For temperatures, other than 45°C,

a deration factor has to be applied as indicated

below. |

|

| |

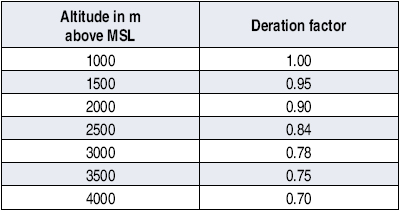

Altitude :

The motors are suitable for altitude upto 1000 m

above mean sea level. For altitudes more than this,

deration factor shall be as per below

STANDARD OPERATING CONDITIONS

|

Power supply |

: |

415 volts, 3 phase, 50 Hz |

| Voltage

variation |

: |

± 10% |

| Frequency

variation |

: |

± 10%

(absolute sum) |

| Ambient

temperature |

: |

45°C |

| Altitude |

: |

upto 1000m. |

|

| |

STANDARD SPECIFICATIONS

PERFORMANCE AND FIXING DIMENSIONS

The motors are manufactured with standard metric

frame sizes,

and they comply with the following standards (latest

versions).

IS: 325 IS:4722

IS:1231 IS:2223

IS:3177 IEC:60034-1

IS: 807

Motors with following steel plant specifications

also can be

supplied on request:

IPSS: 1-03-003 IPSS:1-03-004

For detail dimensions, please refer drawings on page

31-37 in this

publication. |

| |

CONSTRUCTIONAL FEATURES: (MECHANICAL)

STATOR FRAME AND ENDSHIELDS

Made of high quality cast iron conforming to

IS:210, ribbed externally to ensure maximum heat

dissipation. All components are machined on CNC

machines ensuring concentricity and correct

alignment. The windings and working parts are

completely enclosed and air is forced over the

stator body by fan, mounted on

the shaft and protected by a cowl. The feet are

integrally cast with the body. This ensures

sturdiness and resistance to vibrations.

STATOR AND ROTOR

CORES

Both the stator and rotor cores consist of low

loss and high permeability steel stampings which are

assembled under pressure and rigidly secured by end

plates.

ENCLOSURE AND COOLING

Standard crane duty motors have IP55 degree of

protection as per IS:4691. IP 56 & 66 can be

provided on request. The cooling code of motor is IC

411 as per IS:6362.

SHAFTS AND BEARINGS

The shaft is of high grade steel and of

appropriate diameter to withstand the bending and

torsional stresses. All shafts are ultrasonically

tested for any minor flaw in the material. Shafts

are machined to extreme fine limits to ensure fit

and interchangeability of bearings. The motors are

provided with single shaft extension.

Special shafl extensions like:

change in diameter and length,

-

taper shaft, with threaded end, and with

hexagonal nut and lock washer.

-

double shaft extensions, (cylindrical &

taper) are available on request.

|

| |

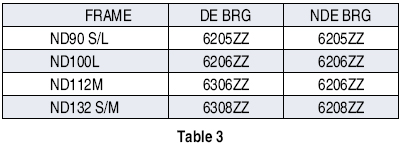

Motors are provided with deep groove ball

bearings. They are mounted with extreme care in dust

proof housing. (Refer bearing size table for

details). Sealed bearings are provided for motors

upto frame 225M. Grease lubricated bearings are used

on frames 250 and above. The correct amount of

grease is filled in the bearings during

manufacturing. On line greasing facility is provided

for 250 frame & above to facilitate greasing of

bearings without dismantling the motor.

For provision of insulated bearings, please refer to

CG.

PRABAL 'E' SERIES MOTORS

PRABAL SERIES MOTORS:

(Bearing references for single shaft extension)

TERMINAL BOX

Terminal box is provided with IP55 degree of

protection. The box can be turned through 3600 in

steps of 900 to give cable entry from anyone of four

positions. The terminal boxes are suitable for BS

screwed conduit. However, fittings like double

compression type cable glands are available on

request.

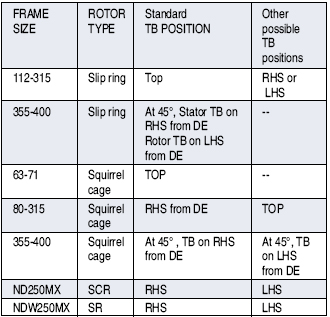

Terminal box position can be provided as per table

below:

SLiPRING AND BRUSH GEAR

All sliprings are made of cupro-nickel. The slip

ring unit is having high insul~tion resistance

ensuring minimum wear and breakdown. The brush

holders are assembled as a complete unit which can

be easily replaced. The slipring enclosure is

dustproof & has a cover with accessibility for

inspection. The slip rings are epoxy moulded /

fabricated type as per requirement.

MOTOR GO. SQ.

For large no. of starts, it is necessary that the

accelerating time of the system should be as small

as possible. For this purpose, total inertia of the

system (motor GO sq. + Load GO sq.) should be

minimum. Motor GO sq. value and permissible load GO

sq. are indicated in the tables.

INTERCHANGEABILITY AND SPARES

All Prabal series crane duty motors are built to

standardised designs and all spare parts are

interchangeable.

CONSTRUCTIONAL FEATURES

(ELECTRICAL)

Class of Insulation:

Stator: Class F insulation with temperature rise

limited to class B

Rotor: Class H insulation with temperature rise

limited to class F

Prabal series crane duty motors with higher class

for stator insulation (class H) can also be offered

on request.

WINDINGS STATOR WINDINGS

Stator winding (and rotor winding in case of

slipring motors) consists of enamelled copper wire

impregnated with superior quality class F varnish

which is rigid at all working temperatures. Stators

in motors with frame 280 & above are manufactured

with vacuum pressure impregnation process as a

standard. All rotors irrespective of frame size are

processed with vacuum pressure impregnation. This

gives added electrical & mechanical strength to the

winding for high number of starts. The varnish has a

high insulation resistance and excellent resistance

to moisture, saline atmosphere, acidic/ alkaline

fumes, and also to oil and grease. The

insulation gives complete reliability under all

atmospheric conditions, including humid tropical

climates. Stator and rotor wound packs are subjected

to surge test before impregnation.

ROTOR WINDINGS

1. Wound rotor

Rotors of slip ring motors are wound and impregnated

similar to stator windings. In addition, rotor

windings are braced with resiglass banding. This

gives protection against centrifugal forces

experienced by overhang during overs peed and

frequent reversals. Gelcoat is provided on the

winding overhang for better

consolidation and protection from vibration. Strip

wound rotors are provided on frames 355 and above.

2. Cage rotor

Rotors are of pressure diecast aluminium upto 355

frame. They are designed for high starting torque,

suitable for high number of starts. Cooling fins

cast integrally with the rotor cage, improve the

cooling action within the motor. All rotors (cage

and wound) are dynamically balanced to comply with

the requirements of IS: 12075

TERMINAL ARRANGEMENT

The terminals are mounted on a moulded base and are

enclosed in a box having an inspection cover. In

case of slip ring motors, three terminals for stator

and three terminals for rotor are terminated in

terminal box with adequate creepage and clearance.

The rotor terminals are in the same box as those of

the stator.

Separate terminal box for rotor terminals is

provided for NDW355LX & NDW400LX frames. This

simplifies wiring and maintenance.

EARTHING

One earthing terminal is provided in the terminal

box and two terminals on mounting feet.

ACCESSORIES:

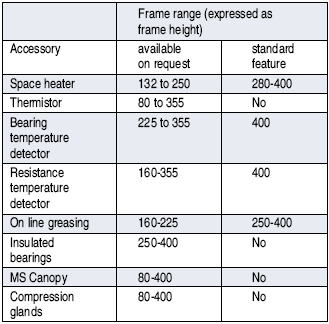

Crane duty motors can be provided with various

accessories as per table below:

Space heating for anti

condensation:

Space heaters are used for avoiding accumulation of

moisture/water in humid atmospheres. In motors upto

200 frame size, motor windings can be heated up to

keep winding temperature above ambient by 5 to 10

degrees, by giving low supply voltage upto 10% of

rated voltage. Supply voltage is to be adjusted by

keeping 20-25% rated current. Thermal protection:

Stator windings can be provided with PTC thermisters

for alarm/trip or PT 100 type resistance temperature

detectors according to the accessories table

provided. Bearings can be provided with PT100 type

resistance temperature detectors as per enclosed

table 6.

ROTOR VOLTAGE

The rotor voltage of the motor is kept such that the

insulation of the rotor and of the associated

switchgear is not unduly stressed during rapid

plugging when rotor voltage can rise to 2 to 3 times

the rated value. Rotor voltage for slip ring motors

is as per performance tables enclosed. Special rotor

voltage can be offered for wire wound rotors with

confirmation from CG.

PULL OUT TORQUE

The pull out torque value at rated voltage is

indicated in the respective tables. Since available

torque varies as the square of the supply voltage at

motor terminals, an allowance for voltage drop in

long cables, live rails and collectors must be

considered. These voltage drops are significant when

motor is operated at pull out point, since current

at this point is much higher than the rated current.

Pull out torque is maximum for 300 starts/hour

class. This high pullout torque ensures rapid

acceleration irrespective of drop in effective

torque due to stepped rotor resistance. However,

care to be taken that gears and other drive

transmission equipments can withstand this peak

torque.

OVERLOAD CAPACITY

The motors can withstand 1.5 times the rated current

for 2 minutes without suffering damage. This feature

makes the motor suitable for severe duties

experienced on the crane or similar applications.

LIFE OF THE MOTOR

Crompton Greaves crane duty motors are designed and

manufactured with carefully selected and tested

insulating materials to ensure long services. The

life of the motor mostly depends upon the life of

the insulating materials since bearings, brush

gears, slip rings etc. can be replaced easily during

normal maintenance.

MAXIMUM PERMISSIBLE OPERATING SPEED

All 4, 6, 8, and 10 pole motors are designed for

withstanding an over speed of 2.5 times rated

synchronous speed or 2000 rpm whichever is less.

VFD CRANE DUTY MOTORS ( Cast Iron)

Crane duty squirrel cage motors when used with

inverter drives give better current control, speed

control & improved operation. Current control is

similar or better than slip ring motors &

maintenance cost /efforts are less than equivalent

slip ring motors. Current control of VFD driven

motors is better than standard squirrel cage motors.

Prabal series Inverter duty motors are provided with

special insulation system suitable to withstand

voltage spikes when fed from inverters. The motors

are provided with following features:

• Vacuum pressure impregnation of stator winding,

this gives less voids & stronger winding.

• Strengthened insulation system for withstanding

voltage stresses.

Standard features:

Base Voltage: 220 volts to 650 volts Base frequency:

50 or 60 Hz Insulation class: Class "F' or 'H' as

required (temp rise limited to class B)

CG make motors are suitable for the following IGBT

drive output

• High frequency in the range of 3kHZ - 6 kHZ.

Voltage rise time> 0.1 sec.

• Voltage spikes up to 1600V and rise time of 0.1

sec.

• Voltage spikes up to 1600V and rise time of 0.1

sec.

• THD < 3%

Mode of operation: Modes of operation of inverter

driven motors are classified according to type of

load & speed range. They are:

• Variable torque

• Constant torque

• Constant power.

|

| |

In case of cranes/hoists, the mode of operation is

constant torque. The typical speed range is from 10%

to 100% of synchronous speed. The speed during

lowering cranes in unloaded conditions may be more.

The limiting speed should not exceed 2.5 times of

rated synchronous speed or 2000 rpm whichever is

less.

The selection of frame size for various duty type &

starts shall be as per table enclosed.

For higher cable length from drive to motor, use

suitable dv/dt filters & a lower switching

frequency.

Use of insulated bearing at non driving is recommended

for frame size above 315 to reduce bearing failure

due to shaft currents.

Use of thermisters for frames upto 250 & resistance

temperature detectors for frame 280 & above is

recommended.

Additional losses & temperature rise:

Harmonics of voltage & current in a cage induction

motor supplied from a converter cause additional

iron & winding losses in the stator & the rotor.

There is no simple method to calculate the additional

losses & no general statement can be made about

their value.

When the motor is tested with converter supply at

rated load, base voltage & base frequency, the

permissible temperature rise will be within the

limits of the insulation system used. For example

when a motor havinf class F insulation system is

tested with sinusoidal supply at rated voltage ,

rated frequency & rated load, may have temperature

rise within class B limits. However, when the same

motor is tested with converter supply under same

test conditions, the temperature rise will be within

class F limits. It is assumed that, while testing

with converter supply, the HVF factor of converter

output supply, is maximum 3%.

Hence the outputs of crane duty inverter driven motors

are as listed in the table on page 28-30.

GENERAL REQUIREMENT:

All additional general requirements like accessories,

paint shade, insulation class, degree of protection,

voltage and frequency variation shall be available

at extra cost. The cost structure of extra features

is same as that for standard motors.

DEFINITIONS

The terms used frequently in intermittent duly drive

and hoisting are as bellow:

1. Duty:

Operation of the motor at load including no load and

de- energised period to which the motor is

subjected, including the sequence and duration.

2. Cyclic duration factor (CDF) :

The ratio between the period of loading including

starting and electric braking and the duration of

the duty- cycle expressed as percentage.

3. Starting:

The process of energizing a motor to bring it upto

rated speed from rest.

4. Jogging or inching:

This is an incomplete start during which the motor

does not attain more than 25% of the rated speed.

5. Electric braking:

A system in which a braking action is applied to an

electric motor by causing it to act as a generator.

6. D.C. Injection braking:

A form of braking of an induction motor in which a

separate dc supply is used to magnetise the motor.

7. Plug braking:

A form of electric braking of an induction motor

obtained by reversing the phase sequence of its any

two lines.

8. Regenerative braking:

A system of electric braking in which energy is

returned to the supply system.

INTERMITIENT DUTY TYPE RATINGS.

The basis of the ratings is that of

thermal capability, taking into account,

i) Frequency of starting

(starting class).

ii) Percentage of time during

each operating cycle the motor is energized, (CDF)

iii) The number and type of cycle per hour, (duty class)

iv) and the inertia of the motor and the load.

CLASSIFICATION OF STARTING:

The starting classification for a motor indicates the

maximum permissible number of starts per specified

inertia, taking into account complete starting,

jogging or inching and electric braking. Rating for

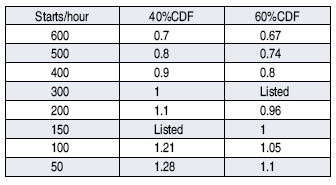

the commonly used starting, i.e. 6,150 and 300

starts/hour class, are listed in this publication.

However, following factors can be used to calculate

output rating for different number of starts and

CDFs.

Squirrel cage motors:

4 jogs or inchings or jerks = 1

start

1 plug braking = 3 starts

1 dc injection braking = 2 starts

1 plug reversal = 4 starts

Slip ring motors:

4 jogs or inchings or jerks = 1

start

1 plug bra~ng = 0.8 starts

1 plug reversal = 1.8 starts

DUTY TYPE :

Crane duty applications can be

classified into duty types S2 to S10. The duty types

are as per table 4 below:

The duty types S2 to S5 are

explained in detail as per below:

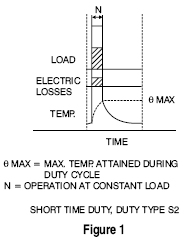

Short time duty (duty type S2) :

Operation at constant load during

a given time, less than that required to reach

thermal equilibrium, followed by a rest and de-

energised period of sufficient duration to

re-establish machine temperatures within 2°C of the

coolant. (See figure 1) The recommended values for

the short time duty are 10, 30 and 90 minutes.

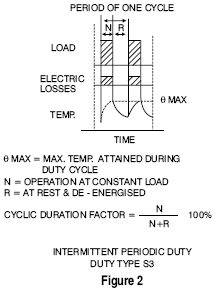

Intermittent periodic duty (duty type S3) :

A sequence of identical duty cycle,

each including a period of operation at constant

load and a rest and de-energised period. These

periods being too short to attain thermal

equilibrium during one duty cycle. (See Fig. 2) In

this duty type, the starting current dose not

significantly affect the temperature rise. Unless

otherwise specified, the duration of the duty cycle

is 10 inutes. The recommended values for the CDF are

15, 25, 40 and 60 percent.

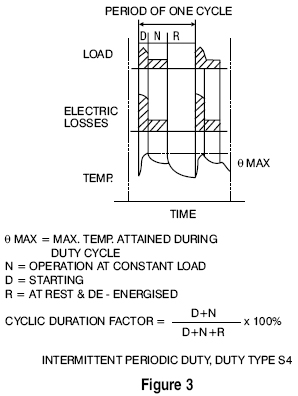

Intermittent periodic duty with starting (duty type

S4) :

A sequence of identical duty

cycles, each cycle including a significant period of

starting, a period of operation at constant load and

a rest and de-energised period. These periods being

too short to attain thermal equilibrium during one

duty cycle. (See Figure 3) In this duty, the

stopping of the motor is obtained either by natural

deceleration after disconnection of the supply or by

means of braking such as mechanical brake which does

not cause additional heating of the windings.

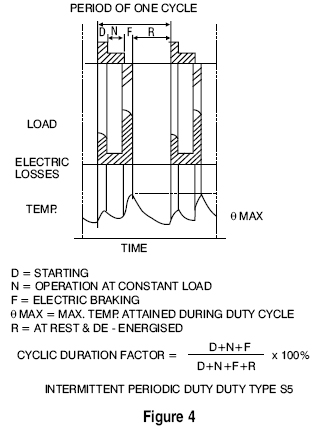

Intermittent periodic duty with starting and braking

(duty type S5)

A sequence of identical duty

cycles, each cycle consisting of a period of

starting, a period of operation at constant load, a

period of rapid electric braking and rest and

de-energised period. The operating cihd rest and

de-energised periods being too short, to attain

thermal equilibrium during one duty cycle. (See Fig.

4) Note : In all above types of duties, the loading

period and rest period of the cycle are so short

that the steady state temperature is not reached.

While working on these identical cycles

continuously, the motor temperature rise must not

exceed the permissible values for a given class of

insulation.

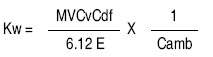

Selection of motors for hoist motions:

For hoisting motor, the power

required shall not be less than that computed from

the following:

Where, derating factor will be

taken as 12%,

Kw = one hour power rating for dc motors & power

rating at (8 - 40%) cyclic duration factor for ac

motors.

M = mass of rated load on hook plus weight of hook

block & wire ropes in tones

V = specified hoisting speed in M/min

E = combined efficiency of gears & sheaves

= (0.93)n x (0.98)m for sleeve bearings

= (0.95)n x (0.99)m for antifriction bearings

= (0.985)n x (0.99)m for hardened profile ground &

oil splashed lubricator, where

n = number of pairs of gears

m = total number rotating sheaves passed over by each

part of the moving rope attached to the drum

Cv = service factor for vertical motion depending on

type of motors,

= 0.67 for ac motors,

= 0.5 for dc motors

Cdf = duty factor

Camb = Derating factor for ambient temperature as per

table 1.

For an ac hoist motor, the specified full load hoist

speed must be obtained at not more than rated

torque, therefore, the calculated full load kw must

be multiplied by :

Where sufficient information is not

available values given in table 9 below for duty

cycles, cyclic duration factor & starting class

corresponding to mechanism class shall be used. The

values given are based on the following formula:

|

|

|

Top |

|

| |

DC Motors |

| |

|

|

INTRODUCTION |

|

| |

Crompton Greaves Ltd, a name synonymous with

rotating machines have DC Motors Technology

inherited from SIEMENS, Germany, the pioneer and

world leader in DC Motors. Today, Crompton Greaves

offers an entire range of world class DC Motors.

The motors are manufactured at Crompton Greaves

Ltd. Ahmednagar factory, an ISO accredited set up

having state - of - the - art manufacturing

facilities. The high quality standards maintained in

manufacturing and testing give superior electrical

and mechanical features - making the motors most

suitable for operating in tropical environments. |

| |

The Ahmednagar factory - manufacturing DC Motors

|

| |

| |

SPECIAL FEATURES |

|

APPLICATIONS |

Fully laminated yoke construction offering

excellent commutation - suitable for 6 pulse

thyristor power supply |

|

Plastic Extruders |

|

Skewed Rotor construction - ensuring low

noise |

|

Printing Machines |

|

Vacuum pressure impregnation for armature

winding - ensuring high insulation strength |

|

Steel Rolling Mills and Wire Rod Mills |

|

High dynamic response |

|

Sugar Industry

|

Compact, low weight and highly energy

efficient |

|

Textile Mills

|

Larger size of bearings - for longer life

and

trouble free operations |

|

Apron Feeders

|

|

Constant / uniform pressure brush holders |

|

Machine Tools

|

|

Easy fitting and retro-fitting of filters |

|

Rubber Industry

|

| |

|

Cement Mills

|

| |

|

Cable Industry

|

| |

|

Paper Mills

|

| |

|

Material Handling |

| |

|

|

|

Laminated Yoke DC Motor manufactured at

Ahmednagar |

|

Aux Mill Duty DC Motors as per IPSS/AISE

Standards are also manufactured |

|

|

|

|

| |

|

|

| |

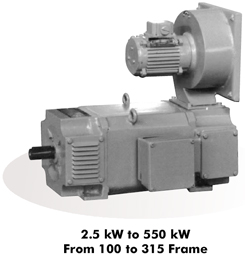

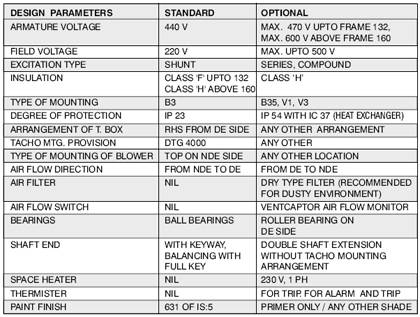

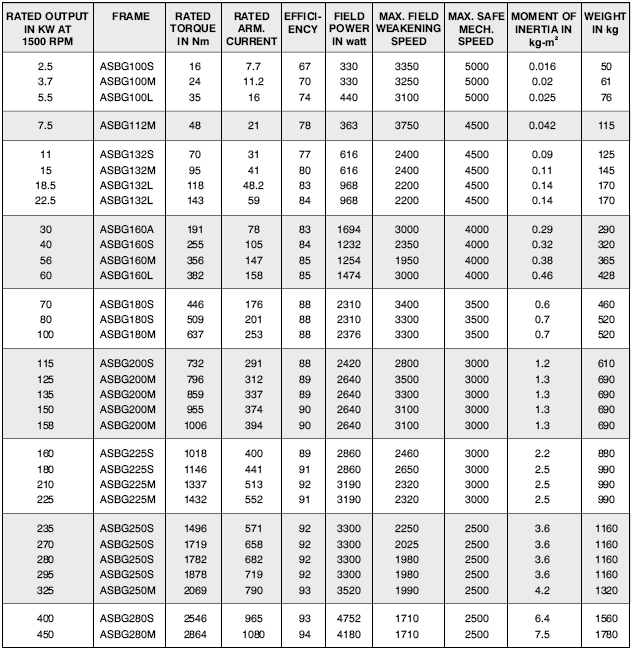

SPECIFICATIONS :Laminated Yoke

|

Laminated Yoke Construction Range : |

|

| Output Frames |

: 2.5 kW to |

550 kW

|

: ASBG 100 to ASBG

315 |

|

| |

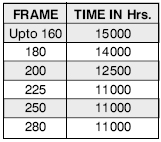

BRUSH

LIFETIME :

|

BRUSH MATERIAL, COMMUTATION :

Practically sparkless commutation with

converter feeding, even under overload

conditions is achieved. As a result, the

brushes have an extremely long life. |

|

|

|

|

|

| |

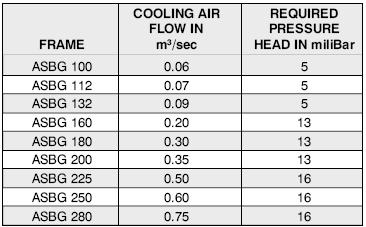

FORCED

COOLING DETAILS

|

|

The blowers of DC Motors have three phase motors

with wide range of winding and supply voltages.

The blower motors are selected strictly in

accordance with the air quantity required and

ensures cool running of motors under the

specified operating loads / overloads. The

terminal box of blower motors are easily

assessible. |

|

| |

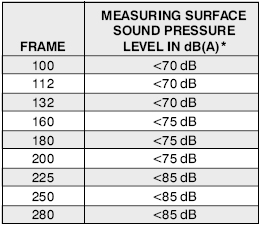

NOISE

LEVEL

|

|

The noise levels of the motors have been

calculated in accordance with DIN EN 21 680 and

are well below the values permitted by EN 60034

- 9. They have been achieved both by means of

design measures and by optimising the magnetic

circuit and the separately driven fans.

* At No Load, with

blower ON, with thyristor supply |

|

| |

| TECHNICAL DATA |

|

|

| |

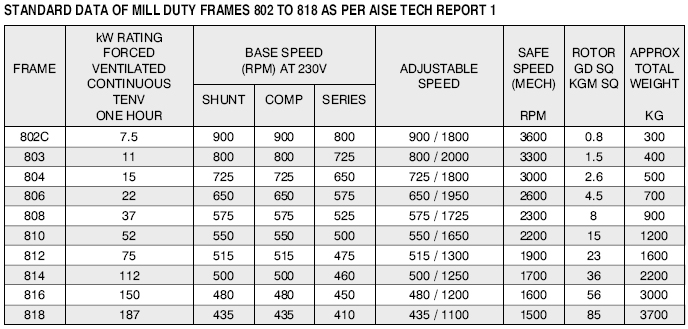

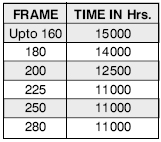

AUX MILL DUTY D.C. MOTORS TO AISE/IPSS STANDARDS

Crompton Greaves Ltd., a name

synonymous with rotating machines backed by its long

proven expertise in the field of DC motors offers the

entire range of state of art Auxiliary Mill Duty 800

series DC motors in frames 802 to 818 from 7.5 kW at 900

RPM to 187 kW at 435 RPM to AISE/IPSS Standards.

These motors are very rugged, reliable and

suitable for steel mills or like applications.

818, 816, 814, 812, 810, 808, 806, 804, 803 &

802 frames are manufactured at CGL, LT Motors Division,

Ahmednagar (Lam yoke DC motor frames 100 to 280 are also

manufactured here). M3 Division is accredited with by

BVQI for ISO 9001 Certification Quality Management

System. |

| |

|

SALIENT FEATURES |

|

|

|

• Conforming to AISE technical report no. 1-1991 /

IPSS 1-03- 002-94. |

|

• Replaceable shaft. |

|

Full speed, half speed and quarter speed designs

available. |

|

• Double

shaft extension 1:9.6 taper with key way paralle to

taper as per AISE or 1:10 taper with key way

parallel to shaft axis as per IPSS. |

|

• Suitable for operations upto 500 volts. |

|

•

Convertible between TENV & TEFV enclosure or with

top mounted blower unit. |

|

• Suitable for operation on 3 phase, 6 pulse

thyristor converter. |

|

• Loose

hanging leads or terminal box as required. |

|

• Class 'H' insulation with class 'F' temperature

rise limits. |

|

• Axial

play of 3 mm approximately of shaft. |

|

• Armature class 'H' with VPI in solventless

polyesterimide resin. |

|

• Brush

position of 45 deg. for easy access for maintenance

(except in case of laminated yoke version). |

|

• TIG welding of armature coil connection to

commutator. |

|

Motor

mounting dimension can be matched to replace 600

series motors to AISE or Russian standard. |

|

• Split / Non split yoke without compensating

winding or non split laminated yoke with

compensating winding. However split yoke is

preferred for 808 & above frames and compensating

type for 812 & above frames. |

|

|

|

| |

|

| |

Top |

|

|

| |

AC

Generators |

| |

|

|

AC Generators |

|

| |

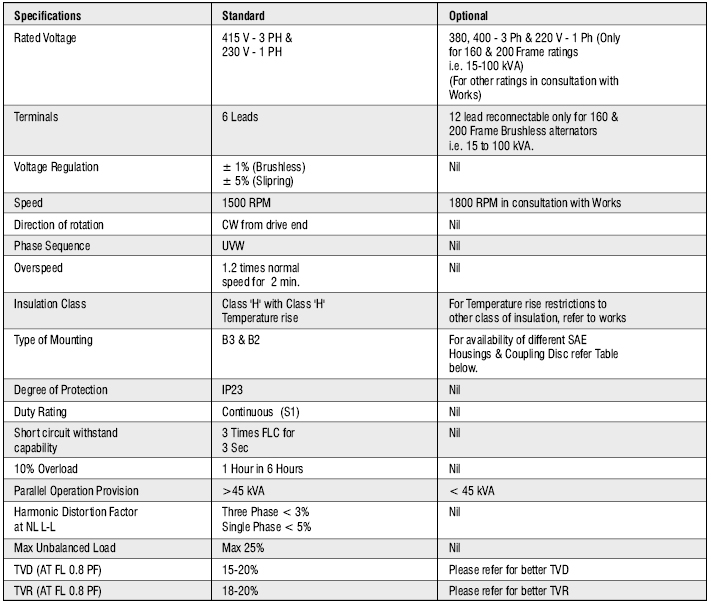

Crompton Greaves AC Generators are state-of-the-art,

self-excited, self-regulated and dependable source

of power.

A modern integrated manufacturing facility for

rotating machines, ISO 9001 certified by BVQI UK,

with structured TQM and 6 SIGMA implementation and

SAP/R3 enabled, also houses dedicated plant for AC

Generators deploying superior techniques and

processes in each specialized field of design,

material

specifications and procurement, CNC machining,

assembly, testing & packing.... with stringent

quality standards predominating throughout.

These generators incorporate advanced European

Technology and are designed for optimum performance

using high-end software solutions. With

well-qualified engineers and technocrats, backed by

a strong R & D Team, Crompton Greaves have fully

harnessed long experience in design and software to

offer a range of innovative, reliable and efficient

AC Generators. |

| |

|

|

| |

SPECIFICATIONS AND OPTIONAL FEATURES :

|

| |

BRUSH

LIFETIME :

|

BRUSH MATERIAL, COMMUTATION :

Practically sparkless commutation with

converter feeding, even under overload

conditions is achieved. As a result, the

brushes have an extremely long life. |

|

|

|

|

|

| |

FORCED

COOLING DETAILS

|

SPECIAL FEATURES |

|

RANGE |

|

APPLICATIONS |

| |

| • Ease of

maintenance with integrated components and

outboard Exciter/Rotating Rectifier. |

| • A reliable

long life with superior class 'H'

insulation. |

| • Higher motor

starting capability. |

| • Compact,

light and sturdy die cast aluminum stator

for frames upto 250, offer superior finish. |

| • Specially

designed compact slipring and brush

assembly. |

| • High

thyristor load withstand capability for

Cell-Phone and Telecom applications. |

| • Short circuit

withstand capability. |

| • Wide range of

coupling discs / adaptor for single bearing

construction suitable for wide range of

Engine makers. |

| |

|

|

|

Brushless AC Generators : |

| • 5 kVA to 625

kVA, in 3 phase, 415 V, 50 Hz, 0.8 pf (lag)

Single or double bearing. |

| • 5 kVA to 40

kVA in single phase, 230 V, 50 Hz, 0.8 pf

(lag) Single & double bearing |

| |

|

Slip-Ring AC Generators : |

| • 5 kVA to 82.5

kVA, in 3 phase, 415 V, 50 Hz, 0.8 pf (lag)

Single or double bearing. |

| • 5 kVA to 20

kVA in single phase, 230 V, 50 Hz, 0.8 pf

(lag) Single & double bearing |

| • 2 Pole

Alternators (both Slipring and Brushless)

are available on request. |

| |

|

|

|

| |

| • Industries |

| • Telecom,

Cell-Phone Towers |

| • Defense |

| • Agriculture |

| • Marine |

| • Hotels,

Hospitals, Commercial & Residential

Complexes, Petrol pumps |

| • Construction

sites, Stone Crushers & hot Mixing plants. |

• Trailer

mounted mobile sets for rental

markets |

| |

|

|

|

| |

| OPERATING

IN DIFFERENT ENVIRONMENTS |

| • For use

of the AC Generator at altitudes higher than 1000 m.

above the sea level, it is necessary to derate by a

factor of 4% for every 500 m above 1000 m |

| • If the

ambient temperature exceeds 40 deg. C, the derating

factor to be incorporated is 4% for every 5 deg. C

of increase. |

| |

|

| |

|

STANDARDS COMPLIANCE |

|

• IEC : 34 |

|

| • BS :

5000 (Part 99) |

|

|

• EN : 50081 |

|

• IS : 4722 & 13364 (Part I & II) with CE mark for

brushless designs. |

|

| |

| MECHANICAL

FEATURES |

| •

Aluminium frame die - cast stator upto 250 and steel

stator for higher frames. |

| • Sturdy

cast iron endshields fixed on to the stator frame by

high tensile screws. |

| • High

quality steel shafts are amply designed to take care

of overload and short circuit stressed conditions. |

| • Sturdy,

dynamically balanced rotors are designed for

withstanding the runaway engine speed and are with

continuous damper cage for high performance under

arduous conditions of parallel operations. |

| • Aluminum

fans for effective cooling extends the winding life. |

| • Screens

or louvered covers on all openings for safety. |

| • Easy

mount SAE adaptors are offered with single bearing

AC Generators to simplify coupling with popular

engines. |

| |

|

|

| |

|

AUTOMATIC VOLTAGE REGULATOR (AVR) |

|

Model |

Frame |

SR 7/3

SR 7/6

UVR 7

SR 7/5 |

132 & 160

Frame

200 & 250 Frame

250L & Above

For Slipring (on request) |

| • Under

Speed Protection with LED indicator. |

| • Over

Excitation Protection with LED indicator |

| • 2

Phase sensing with Senseloss LED Indicator |

| •

Designed for Thyristor load without additional

filter circuits. |

| •

Moulded construction for protection against

shocks, vibrations and adverse atmospheric

conditions. |

| •

Parallel operation facility for SR 7/6 and UVR

7. |

|

|

|

| |

| UNDER

SPEED PROTECTION (with AVR) |

| •Protects

both the AC Generator and V/f sensitive loads. The

AVR has provision for setting the frequency below

which voltage dropping occurs linear to speed. This

feature also enables the prime mover to recover the

speed faster during motor starting |

| |

| WINDING

AND INSULATION SYSTEM |

•The

armature coils of the stator main winding are made

from dual coated, class 'H' copper wires,

Single/Double Layer concentric fractional pitched

winding offers simplicity, reduced overhangs, neat

look while reducing voltage distortion and superior

capability to cope with non-linear loads. The

auxiliary winding in stator provides power to the

AVR, improving the motor starting capability of the

AC Generator.

The insulation system is class 'H'. All wound

components are impregnated in an unsaturated

polyester resin of 200 class temperature. The

impregnation provides much needed rigidity and

protection against the harsh environment, typical

for the AC Generators applications |

|

|

|

RADIO INTERFERENCE |

|

The AC Generators are having negligible Radio

Frequency Interference and meets in general the

limits permitted by VDE 0875 (N) |

|

|

|

WAVE FORMS |

|

A.C. Generators are designed to give an excellent

output wave-form. The total harmonic content of

line-to-line voltage wave-form on no load is less

than 5% as per the limits specified by IEC/IS

Standards. |

|

|

|

OVERLOADS |

|

A.C. Generators are capable of delivering an

overload of 10% for one hour after every six hours

of running. an overload of 10% for one hour after

every six hours of running. |

|

|

|

MOTOR STARTING DUTY |

|

Each kVA of AC Generator is capable of starting 1 HP

of Induction Motor with use of auxiliary winding

except for Submersible Pump & Lift Duty

applications. (Upto 200 frame slipring type only) |

|

|

|

VIBRATION AND NOISE |

CNC machining with close tolerances and repeat

Accuracy for uniform air - gap and rotor dynamic

balancing for low vibrations ensure efficient,

smooth and silent

performance. |

|

| |

TERMINATION

| •

Integral Terminal Box is provided for higher

reliability. |

| • Top

Terminal Box with side cable entry ensures

wiring flexibility. |

| •

Spacious terminal box accommodates all types,

including aluminum cables |

|

|

|

| |

TEFC Motors |

Energy Efficient Motors (EFF-1) |

Flame Proof Motors |

Crane / Hoist Duty Motors |

D.C. Motors |

AC Generators Alternators

Induction Motors |

Monoblock pumps |

Self priming pumps |

Submersible pumps |

|

|