| |

PRODUCTS ::::::::::::::::: |

| |

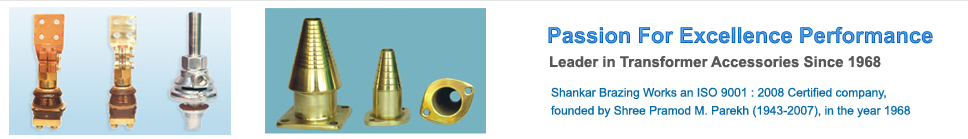

Manufacturers & Exporters Of Transfer Spares, Transformer Bushing Metal Parts, Bus Bars, Jumpers, Crimping Sockets, Transformer LV Windings, Terminal Connectors, Spades, Breathers, Glands & All Types Of Non Ferrous Components |

| |

|

| |

| Porcelain Bushing Metal Parts |

|

For Power / Distribution/ Cast Resin / Dry Type/ Furnace/ Loco /Induction/ Booster / CT & PT Transformers

Standards Followed:

Manufactured in accordance with Indian Standards – IS : 3347, Din Standards – 42530- 42531 – 42532, Bs 2562 and also as per customers specifications and drawings. |

|

| |

|

| |

| Copper / Aluminum Fabricated Busbar |

|

-

High conductivity & High purity copper flats are fabricated & brazed as per customers requirement on High End technology machineries Ensuring Best Quality Standards, Highest Accuracy and Super Quick Deliveries in an ISO 9001 assessed environment.

-

Raw Material Specification’s: Electrolytic Tough Pitch (ETP) copper is used with purity of Copper to 99.90% and Conductivity to - with 100 % IACS (International Annealed Copper Standard) as per ASTM B187).

-

Temper of Copper Busbars: Annealed (soft), ½ hard (Cold worked), Full hard (Cold worked).

-

Processes: Cutting, Forming, Punching (Holes / Slots), Bending, Tapping, Plating (Tin. Nickel, Silver)

-

Bending: The minimum bending radius for copper flat is equal to the thickness of the flat.

The minimum bending radius for aluminum flat is equal to twice the thickness of the flat.

- No surface roughening occurs at the bend of the flat. Any desired shape can be given to the busbar.

- 100% Flat Surface at connections for complete Matting even at the acute bends

|

|

| |

|

| |

| Copper / Aluminum Laminated Flexible Jumpers & Connectors |

|

| Copper laminated flexible jumpers are manufactured by laminating high conductivity, electrolytic grade copper foils. These laminated foils are then sweated or pressure welded / fused as per customer’s requirements. Such copper jumpers carries the same current as that of Busbars as they have a constant cross section over the whole length giving a nil millivolt drop. So these jumpers are a best substitute for solid busbars..

Our Copper flexible jumpers are widely used in following Industries: Transformers switchgear’s, power plants, Electric locomotives, furnaces, chemical plants, electricity boards & all current carrying equipment manufacturing Industries.

Copper flexible jumpers are manufactured in all possible shapes & sizes as per customer’s requirements. Some of various shapes are shown |

|

| |

|

| |

| Connectors, Spades, Terminal Connectors |

|

Copper laminated flexible jumpers are manufactured by laminating high conductivity, electrolytic grade copper foils. These laminated foils are then sweated or pressure welded / fused as per customer’s requirements. Such copper jumpers carries the same current as that of Busbars as they have a constant cross section over the whole length giving a nil millivolt drop. So these jumpers are a best substitute for solid busbars..

Our Copper flexible jumpers are widely used in following Industries: Transformers switchgear’s, power plants, Electric locomotives, furnaces, chemical plants, electricity boards & all current carrying equipment manufacturing Industries.

Copper flexible jumpers are manufactured in all possible shapes & sizes as per customer’s requirements. Some of various shapes are shown |

|

|

| |

ENQUIRY ::::::::::::::::: |

| |

*

Indicates Compulsory Fields |

|

|

| |

|

|