|

| |

|

|

|

| |

|

|

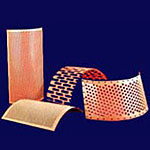

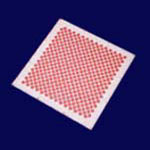

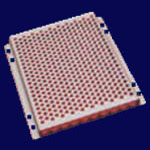

Metal Perforated Sheets, Metal Perforation, Perforated Sheets, Perforated Screens, Perforated Plates, Metal Perforated Sheets, Expanded Sheets, Wire Mesh, Crimped Mesh, Welded Mesh, Chain Links, Hdpe Mesh

|

|

|

| |

|

FINISHED PERFORATED SHEETS

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

Required Details For Wire Cloth Orders |

|

|

1. |

Quantity : number of pieces and/or rolls. |

2. |

Dimensions : length and width of pieces and/or rolls. |

3. |

Material |

4. |

Aperture width : w Mesh count ( per liner inch ) or number of meshes per cm2 may likewise be stated instead of the aperture width. |

5. |

Wire diameter : d |

6. |

Type of weaving processing : if necessary |

7. |

Post weaving processing : if desired |

8. |

Shaped parts filters : provide samples, sketches or drawings, preferably with permissible tolerance. |

9. |

Samples : should you have a sample of the wire cloth employed so far, kindly send it to us. We shall then determine it in our laboratory. |

10. |

Repeat order : so as to furnish you with the correct material either let us have a roll-label or provide the exact technical date of previous order. |

|

|

|

|

s |

|

| |

|

Types of Wiremesh |

| |

|

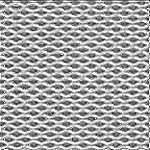

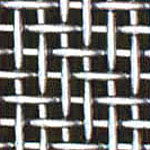

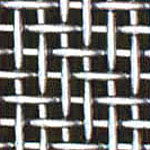

| :: Plain Weave Wire Cloth |

Each wrap wire passes over and under the successive weft wire and vise versa resulting in precise mesh opening and maximum cloth stability. The standard cloth for all purpose. |

|

|

|

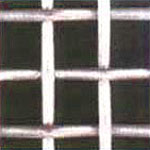

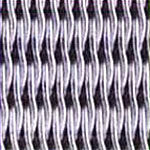

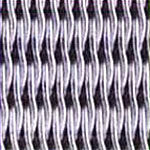

| :: Twill Weave |

The wrap wire passes over and under two weft wires and vise versa. This type of weave allows the use of larger wire diameters to meet process requirements. |

|

| |

|

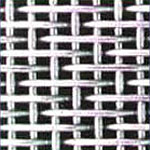

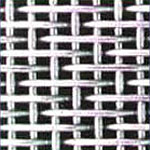

| :: Plain Dutch Weave |

| Weave pattern similar to plain woven cloths, however, the wrap wires are larger and spaced farther apart than the weft wires. Mainly used for precoat filters and vacuum filters. |

|

| |

|

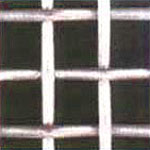

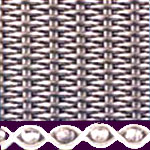

| :: Dutch Twill Weave |

A Dutch Weave, but woven in a twill pattern which enables twice as many weft wires to be woven in the same area as a Plain Dutch Weaves to achieve a finer filter opening . Typically produced for very fine filtration application- 10 micron and finer. |

|

| |

|

| :: Tele Weaves ( 5 heddle-Atlas ) |

4 over 1 under weave pattern. This weave permits the use of extremely strong wires with fine mesh opening resulting in a smooth and wear resistant surface. Used in vacuum filters, centrifuges, dewatering sieves and distillation columns. |

|

| |

|

| :: PZ-Microdur Cloth |

A Reverse Plain Dutch Weave. The warp wires are smaller and spaced closer together than the weft wires. This weave allows the use of high tensile wires which offers the most durable and stable fine filter cloth.

The Reverse Twilled Dutch weave ( KPZ-Microdur ) is woven under the same preferences and gives in special versions extreme rigid cloths with filtration grade down to 45 micron. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

We are leading Manufactur of Metal Perforators, Metal Perforation, Perforated Screens, Metal Perforated Sheets, Wire Mesh, Welded Mesh, Cable Trays, HDPE Mesh, Conveyor Belts, Radio Grills, Perforated Sheets, Perforated Plates, Expanded Metal, Perforated Sheets, Crimped Mesh, Vibrating Screen, Chain Link, Demister Pad, Shifter |

|

|