Dynamic Balancing Services |

|

|

|

|

|

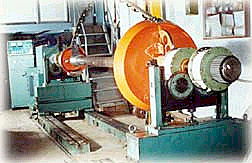

Capacity Upto : Weight 10 Tones, Dia 4 mtrs, Length 7 mtrs |

|

Condition Monitoring / Vibration Consultancy |

|

|

|

|

|

Vibration Analyzer (5050) |

Dynamic Balancer (6050) |

|

As you are aware that excessive vibration on any rotating machinery will severely damage its many important parts like rotary elements, Bearings, Shafts etc. To avoid a major breakdown of the machinery due to the above problems it is always advisable to get it Dynamic Balanced any type of rotary elements before assembly as well as periodical checking and Condition Monitoring / Vibration Analysis of the rotating parts of our plant machineries & corrections thereafter can solve your vibration problems. |

The 6050 offers solutions for Vibration Measurement, Condition Monitoring, Frequency Analysis and Field Balancing all these four application in a single, portable, rechargeable battery operated unit, which fits into a briefcase. The microprocessor controlled unit makes all these tasks easy for the user. Acceleration. Velocity. Displacement or bearing Spike can all be measured with the 6050. In problem cases such as induction motors, where there are normal fluctuation in the vibration readings, the unit will report minimum, maximum and mean of 20 successive reading. The readings can also be downloaded to a PC for monitoring / printing. |

|

|

|

|

|

|

|

|

|

|

|

Designed & Hosted by : MID Promoted by : GID